KEO BLADE CARBON

A FRENCH MOVEMENT, MADE BY LOOK

You'll find what you're looking for

ORIGIN

MADE BY LOOK

We are driven by one obsession: to provide each and every cyclist with performance products of the very highest standard. The desire to constantly improve our pedals has pushed us to explore the advantages of ceramic bearings, with the aim of making the technology accessible to a majority of cyclists.

This innovative idea is implemented in the BLADE CARBON pedal: our elite-level, top-of-the-range weapon designed for pure racing performance. The unique, patented BLADE technology is combined with the unequaled properties of ceramic bearings and LOOK’s signature power-to-weight ratio, ensuring the pedal comes straight in as a reference on the market.

THE PROFESSIONAL TEAMS' PEDAL OF CHOICE

The choice of champions

6 UCI WORLD TOUR teams including Movistar, Astana Qazaqstan Team and Team Cofidis have chosen the KEO BLADE CARBON to accompany them during the 2023 season.

Lightweight, aerodynamic and powerful, the pedal provides the riders with an incredible platform to keep improving and optimizing performance on the road to victory.

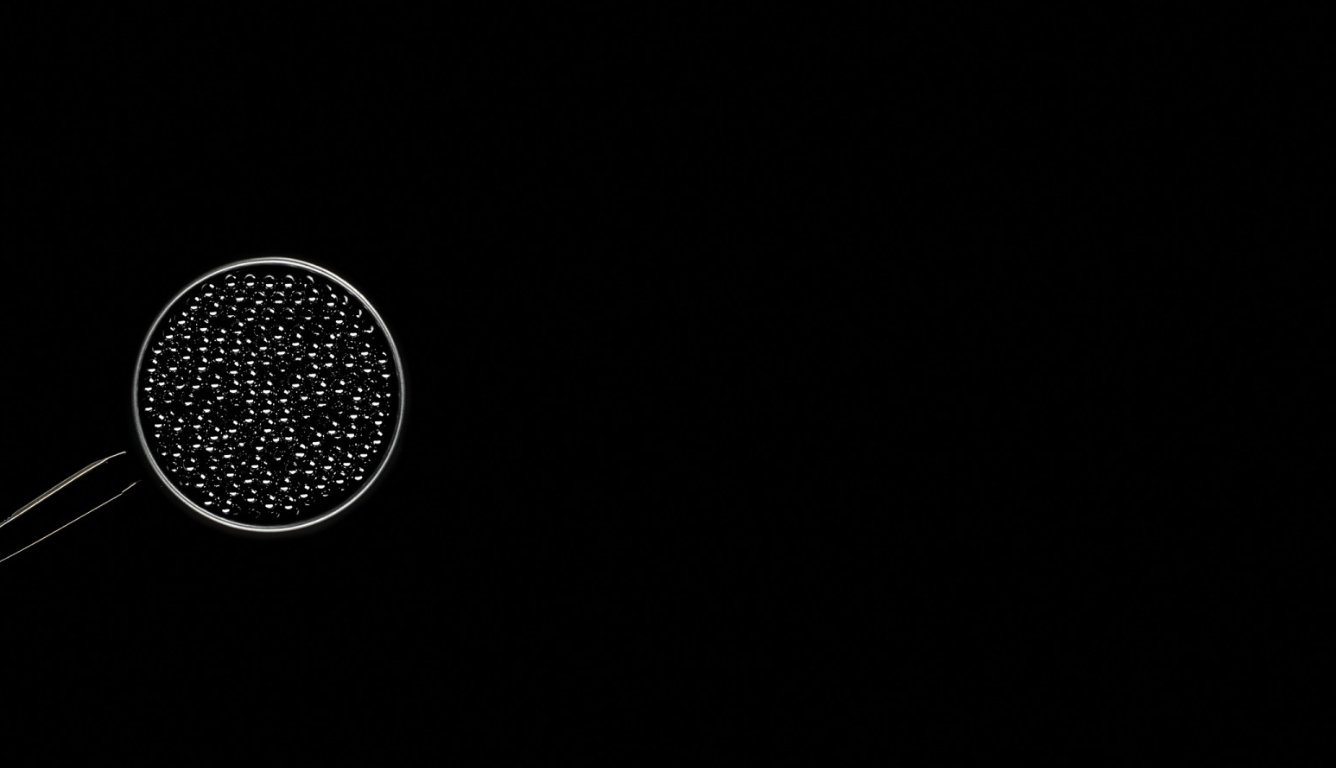

CERAMIC BEARING

FASTER - LONGER

Every component, every ball is meticulously selected to ensure the highest level of quality and performance. The balls are precisely calibrated one by one by a machine, down to the micro-meter. They are then ordered according to size in perfectly- adapted rings, with the result that every bearing has a totally unique structure.

LONGER LIFE

A long lifespan is the main advantage of ceramic bearings. Rounder and harder than traditional balls, they are less sensitive to dust or deposits and guarantee consistent, durable performance. Furthermore, ceramic is not subject to corrosion. These physical properties ensure the bearings have a lifespan 4 to 6 times longer than standard steel bearings.

SMOOTHER

Reduced friction is the best-known and most characteristic advantage of ceramic bearings. The perfectly circular shape and the hardness of the balls combined with ceramic-specific, optimized greases allows for an 18% reduction of the frictional forces applied to the bearing.

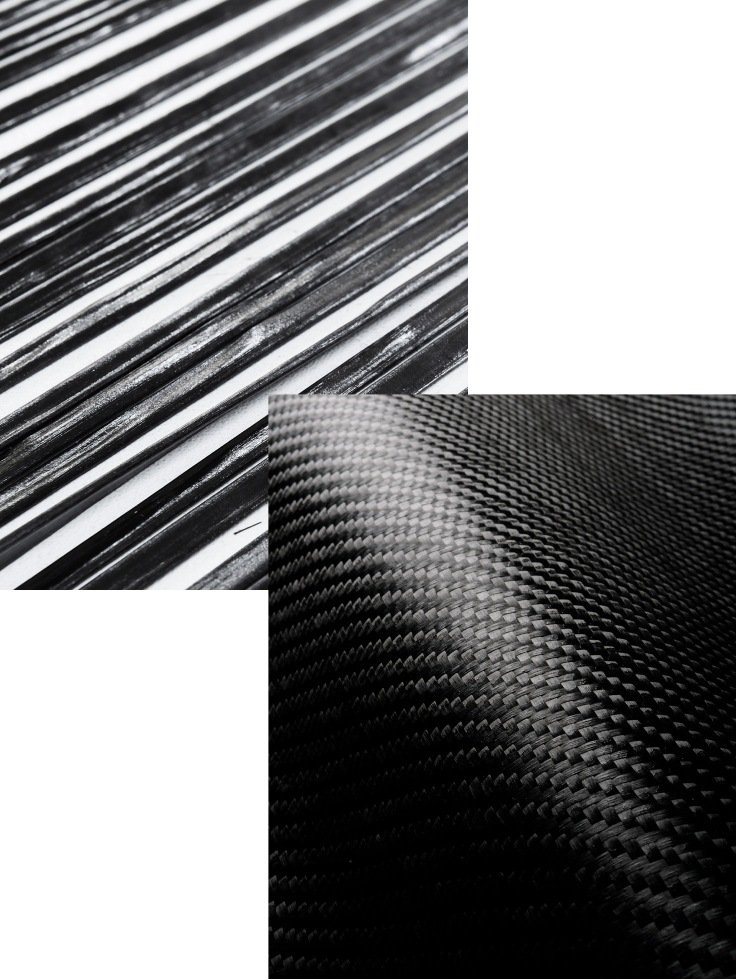

DESIGNED & MANUFACTURED BY LOOK

Since LOOK’s beginning in the bicycle world when metals were king, our material of choice has always been carbon. For over 30 years LOOK has developed in its own factories a unique expertise and a vast know-how in the carbon field to reach specific desired properties.

Once the optimal shapes had been created, our engineers work on the processes and on the carbon for each areas of the pedal in a very precise manner in order to achieve our goal : the creation of ultimate aerodynamic and light pedal.

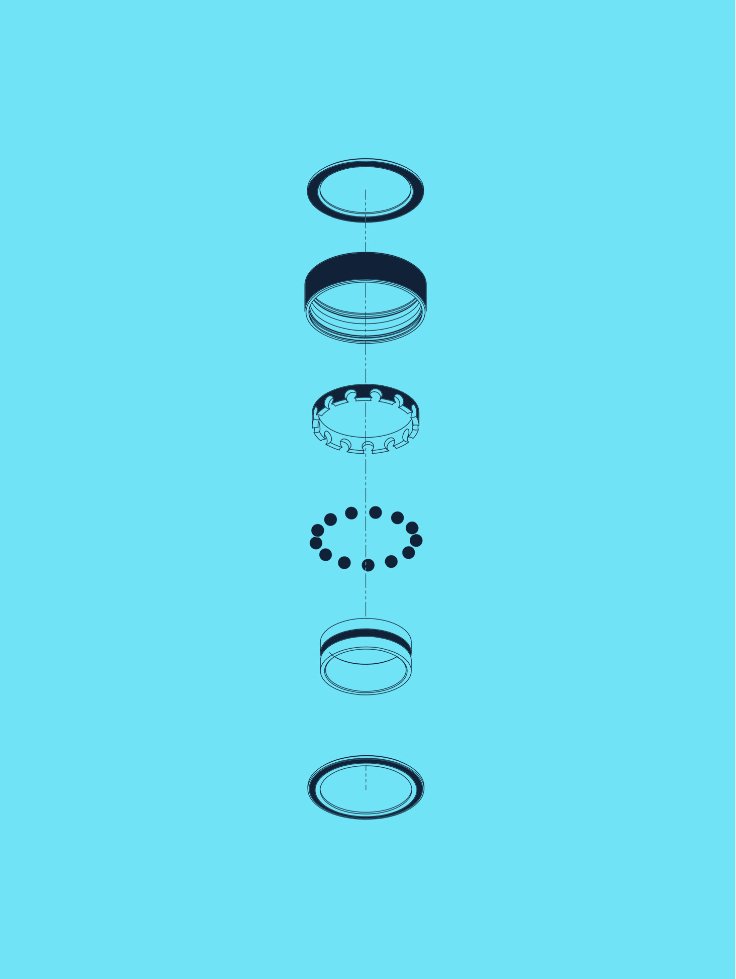

TECHNOLOGIES

The use of a carbon blade instead of a conventional metal spring offers numerous advantages:

- The “blade – lever” system is 20% lighter than a standard “spring – lever” system.

- The carbon blade blends fluidly into the shape and volume of the pedal, improving the overall aerodynamic properties of the product.

- The BLADE technology revolutionizes the engagement/ disengagement experience whilst offering firm and secure support. The bowing of the blade when un-clipping means the required disengagement torque is reached more rapidly in the dynamic of the movement, allowing for faster cleat release.

Pedaling experience is also improved thanks to a firmer lateral stop.

The carbon blade is available in various stiffness options : 12, 16 or 20. The blade can be easily, intuitively and quickly (a few seconds suffice) changed depending on the rider’s clip-in / clip-out preferences.

In order to meet the requirements of the most demanding cyclists, the BLADE CARBON pedals are designed to resist the very worst weather conditions. Particular care is given to each component within the axle to ensure optimal lifespan.

The axle is guaranteed waterproof by IPX7 (full immersion) and IPX6 (rotating pedal exposed to water jets) tests. The design of the outer cap and the inside nut have been revised to meet these requirements.

The full extent of the power a cyclist develops is transferred to the bike – and the road – through the pedals. Without going into extensive scientific detail, the larger the contact area, the more efficient the transfer of energy will be. On the other hand, the wider contact area, the more the weight of the pedal increases.

LOOK engineers have worked tirelessly to pinpoint the areas where energy transfer is optimal, in order to finetune design and reduce any unnecessary surfaces. This careful analysis was key to producing a pedal with the best weight-to-contact area ratio on the market today.