LOOK T20

PERFORMANCE MADE IN FRANCE

Designed to win

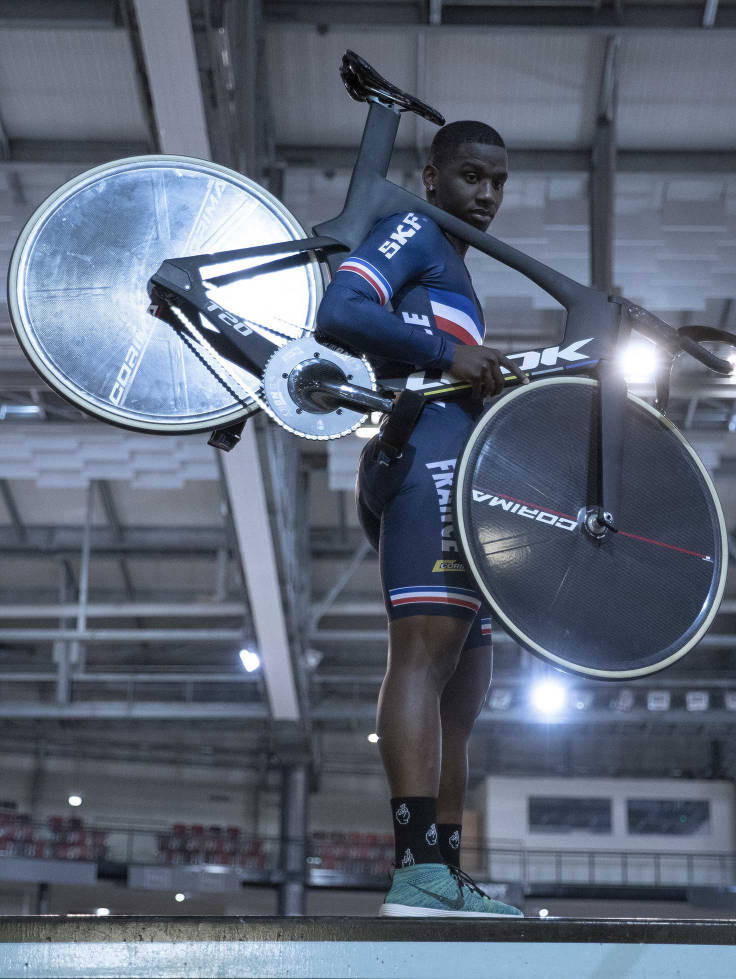

30 years of partnership with the French Federation

As a leader in technological innovation, LOOK has won the most medals in the history of the Summer Games and has always taken pride in providing partner federations and athletes with the best equipment available on the market.

Trust is an integral part of this history: racers and federations trust LOOK to provide them with state-of-the-art equipment when LOOK develops, tests, perfects and distributes these market leading products. The cycling community can only attest to the success of this synergy with the world's biggest competitions.

The next big events will be no exception with the new LOOK T20 track bike. A bike that meets the evolving demands of athletes in terms of power, speed and endurance.

LOOK engineers and carbon experts have worked tirelessly, focusing on the interaction between athlete and bike to achieve new standards of performance on the track.

14 GOLDS, 43 MEDALS IN TOTAL SINCE 1996

DESIGNED & MANUFACTURED BY LOOK

WHEN CARBON SHINES LIKE GOLD

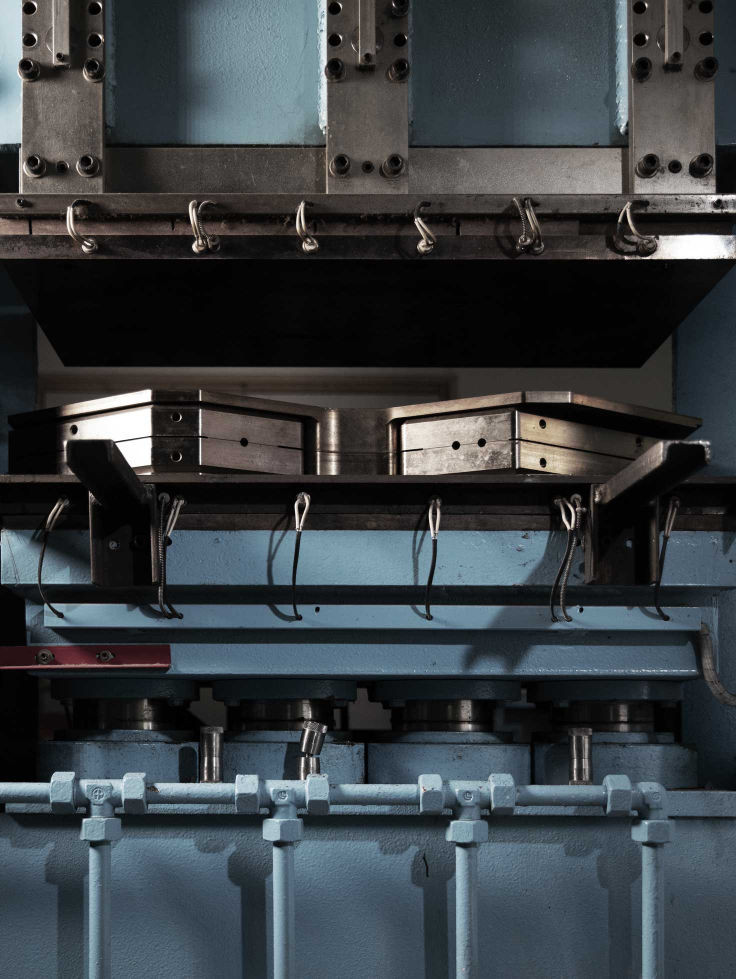

Since LOOK's beginnings in the cycling industry, when metal was king, carbon has always been a material of choice. For more than 30 years, LOOK has developed a unique know-how and expertise in carbon processing in its own factories in order to obtain high performance properties.

Once the optimal shapes have been designed, our engineers work in a very focused way on the processes and the laying of the carbon at all points in order to reach the ultimate goal: the production of an ultra-fast frame, not only thanks to its aerodynamic properties but also thanks to its lightness, its rigidity and its excellent grip.

The weaving of the carbon is an essential factor. It is a matter of selecting the right fibers for each area of the frame, their orientation, their thickness (number of layers), as well as the placement of reinforcements in certain key areas. The bottom bracket area, for example, must be able to withstand higher forces than the head tube. The same is true for every part of the frame and fork. The expertise LOOK brings to this detail work makes all the difference.

THE PERFORMANCE MADE IN FRANCE

Nevers - Burgundy

LOOK imagined, designed, prototyped, tested and produced the LOOK T20 in its workshop in Nevers, France.

The LOOK T20 is the result of a state of the art development process, put in place to design the most advanced performance bike we have ever produced. French athletes will be proud to ride the LOOK T20 "Made in France".

100% MADE IN FRANCE

Aerodynamics

are absolutely key

Of all the disciplines on the program for major competitions - road, CLM, track, MTB, BMX - track bikes have the highest average speeds.

At LOOK, engineers work with athletes to help them get as close to 100% power transfer between themselves and their bike as possible. A true collaboration to optimize every element of performance using cutting-edge methods: from analyzing the performance of previous prototypes, to hours of CFD evaluation, to confirming these results on the track and in one of the most recognized wind tunnels in the industry.

- 11% drag reduction

- 10% lighter than its predecessor

- The LOOK T20 offers + 27% power transfer thanks to an optimized stiffness-to-weight ratio

- At full speed on the track, athletes gain 30 Watts, simply the length of a bike at the finish line for a 200 meter sprint!

4 years of research and development

LOOK & CORIMA

Design integration

Different rear triangle configurations were tested in a wind tunnel on a prototype modular frame to confirm the CFD results simulating the interaction between the frame and the rotating rear wheel.

LOOK is able to provide its athletes with complete feedback (from tests performed in two different wind tunnels) on the CORIMA wheels associated with the LOOK T20 frame. The CORIMA Track wheels are the best in their class on the market, and perform even better when mounted on the LOOK T20.

Aerodynamic thru axles have been used on the front wheel of the R96 bike for the last few years. The combination of CORIMA wheels and the LOOK T20 will now allow the use of thru axle technology on the front and rear wheels.

800 Grams lighter than R96

Even lighter and stiffer

UCI LIMIT OF 6,8 KG IS ACHIEVED

Track racers are so powerful that they require a higher level of bike to transfer all their power to the wood track. That's what track bikes are made for and LOOK's expertise in this area is unmatched.

The engineers aim to obtain the highest possible rigidity to ride at the highest speeds on the smoothest surfaces of all cycling disciplines: a wooden track.

Aerodynamics and stiffness are essential but we must never forget that many track events are run from a standing start. That's why the stiffness/weight ratio is always at the center of LOOK teams' and athletes' concerns.

This factor is considered at every stage of product development, from the design of the parts and manufacturing processes to the application of the final carbon layer, including the application of a finish that only impacts the weight of the frame by a few grams.

- A bottom bracket 25% stiffer than the R96

- Rear triangle 12.5% stiffer than the R96

- Head tube 12% stiffer than the R96

- Head tube 12% stiffer than the R96.

A STILL UNRIVALED ZED CRANKSET

The ZED one-piece track crankset was developed before the 2012 Games and remains unmatched 8 years later. It is simply the lightest and stiffest track crankset on the market. It's also the only crankset that allows for crank length adjustment through the patented Trilobe design.

The bike is developed in symbiosis with the crankset, taking into account the overall rigidity. Our engineers never consider the components separately, but rather how they function as a whole.

The one-piece composition of the crankset allows for perfect control of the carbon layers in all parts of the frame, eliminating the difficulties of crank and axle joints, molding or gluing of inserts, or post-machining of these inserts.

UP TO 200% STIFFER THAN ANY OTHER CRANKSET

A UNIQUE REAR THRU AXLE

COMPATIBLE « STANDARD » WHEELS

Thru axles made their debut on the R96 front wheel. The goal was to improve torsional stiffness at the front of the bike while reducing weight and improving aerodynamics, as engineers removed the entire surface (the "S" of "SCx") of the nuts used to tighten the front wheel.

The next step was to implement the same gains at the rear of the bike, the engineers succeeded in doing so on the LOOK T20 and went even further. They developed a thru axle for the rear wheel, the cleanest ever seen on a track bike. Even better, it allows for structural stiffening of the rear dropouts, areas that are "open" and therefore benefit greatly from the extra stiffness.

The torsional stiffness of the rear triangle is globally improved thanks to the through axle, adding to the gains already obtained with the new materials and processes.

Maximum adjustability

- 4 sizes – from the smallest bike we can make to the largest bike the UCI allow;

- 2 ZED crankset models combined with 6 available crank lengths;

- 18 stem lengths from 55mm to 140mm in 5 mm increments and which are adjustable to any angle;

- A new seat post offering 4 seat tube angles depending on how and in which direction the seat post clamp is installed.

The T20 does not require cutting the frame in order to adjust the saddle height. It is now the seat post that has to be cut (and can be easily replaced if necessary) and can then be adjusted with up to 15mm of spacers under neath.

The SPEED version is delivered with LOOK's TRACK HANDLEBAR.

The TT version is delivered with LOOK's AEROFLAT TT HANDLEBAR with AERGO EXTENSIONS which are also in a class of their own when it comes to aerodynamics and adjustability.

SAFETY, AERODYNAMICS AND WEIGHT ARE UNDENIABLY IMPROVED